Cooled or Uncooled?

Thermal imaging cameras with a cooled detector offer some advantages over thermal imaging cameras with an uncooled detector. However, they are more expensive. A modern cooled thermal imaging camera has an imaging sensor that is integrated with a cryocooler, which lowers the sensor temperature to cryogenic temperatures. This reduction in sensor temperature is necessary to reduce thermally-induced noise to a level below that of the signal from the scene being imaged.

Cryocoolers have moving parts made to extremely close mechanical tolerances that wear out over time, as well as helium gas that slowly works its way past gas seals. Eventually a rebuild for the cryocooler is required after 10,000-13,000 hours of operation.

Advantages of uncooled cameras beg the question: When better to use cooled thermal imaging cameras for R&D applications?

The answer is: it depends on the application.

If you want to see the minute temperature differences, need the best image quality, have fast / high speed applications, if you need to see the thermal profile or measure the temperature of a very small target, if you want to visualize thermal phenomena in a very specific part of the electromagnetic spectrum, or if you want to synchronize your thermal imaging camera with other measuring devices… a cooled thermal imaging camera is the instrument of choice.

Comparison Examples

High Speed

These IR images compare the capture results of a tire rotating at 20mph. The one of the left was taken with a cooled thermal imaging camera. One would think the tire is not spinning, but this is the result of a very fast capture rate of the cooled camera that has stopped the motion of the tire. The uncooled camera capture rate is simply too slow to capture the rotating tire causing the wheel spokes to appear transparent.

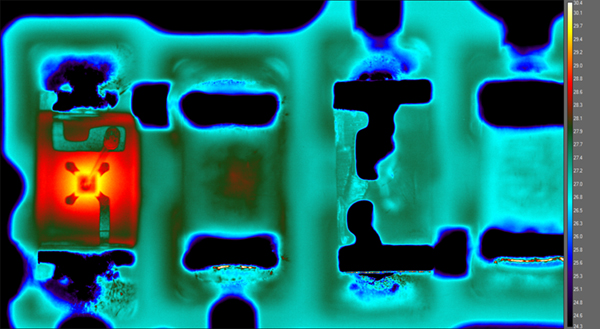

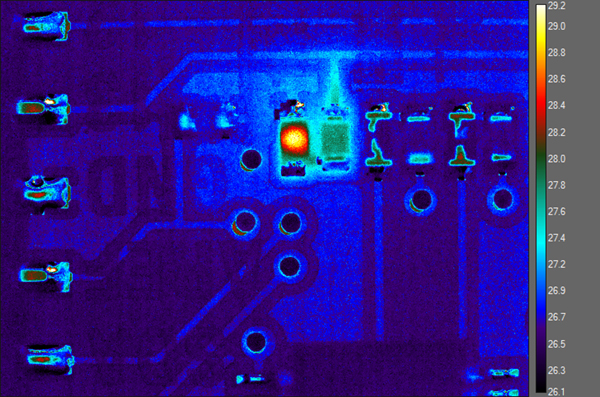

Spatial Resolution

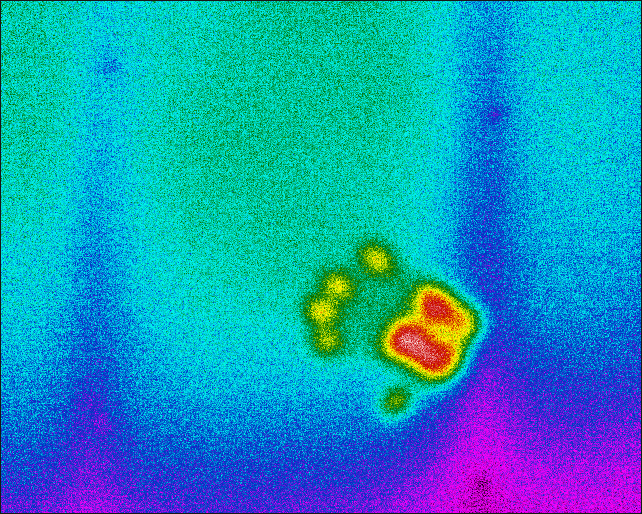

The thermal images above compare the best close-up magnification that can be achieved with a cooled and uncooled camera system. The image on the left was taken with a 4× close-up lens and 13μm pitch cooled camera combination resulting in a 3.5μm spot size. The image on the right was taken with a 1× close-up lens and 25μm pitch uncooled sensor resulting in a 25μm spot size. Cooled cameras typically have greater magnification capabilities than uncooled cameras due to sensing shorter infrared wavelengths. Because cooled cameras have greater sensitivity characteristics, lenses with more optical elements or thicker elements can be used without degrading the signal to noise ratio allowing for better magnification performance.

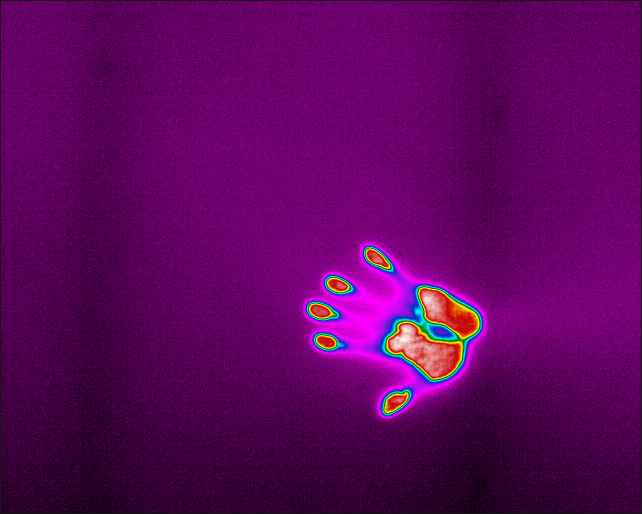

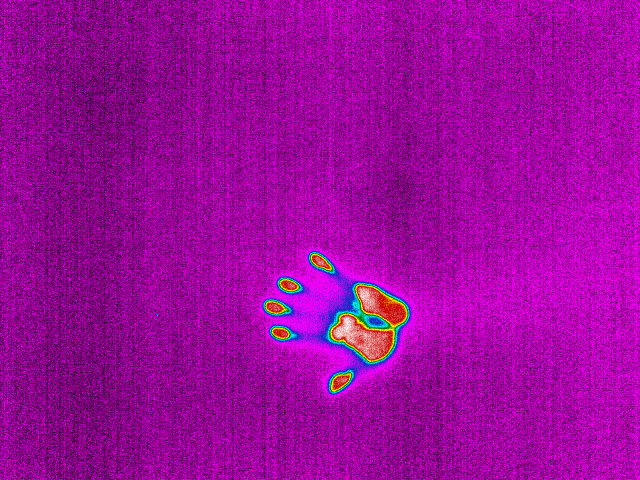

Sensitivity

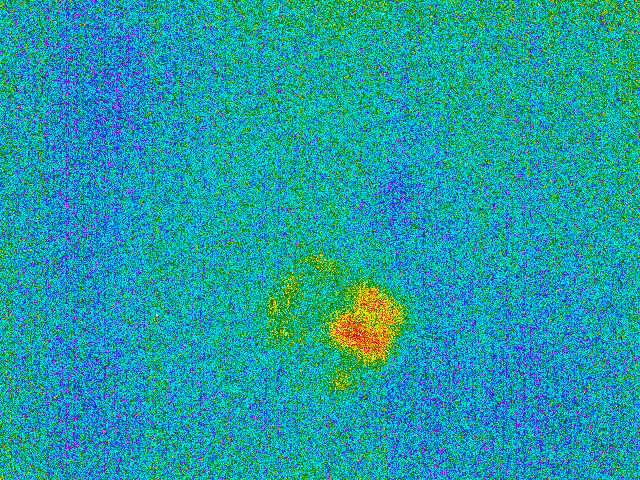

It is often difficult to fully appreciate the value offered by the improved sensitivity of cooled thermal cameras. How do you get a feeling of the benefit from a 50mK sensitivity uncooled thermal camera in comparison to a 20mK sensitivity cooled thermal camera? To help illustrate this benefit we ran a quick sensitivity experiment. For this comparison we put our hand on a wall for a brief few seconds to create a thermal handprint. The first two images show the handprint immediately after the hand was removed. And the second set of images shows the thermal handprint’s signature after two minutes. As you can see, the cooled camera can still see most of the thermal signtature of the handprint, whereas the uncooled cameras only shows the partial remains of the handprint. The cooled camera clearly can detect smaller temperature differences and for longer durations than the uncooled camera. This means the cooled camera will provide better detail on your target and help you detect even the faintest of thermal anomalies."

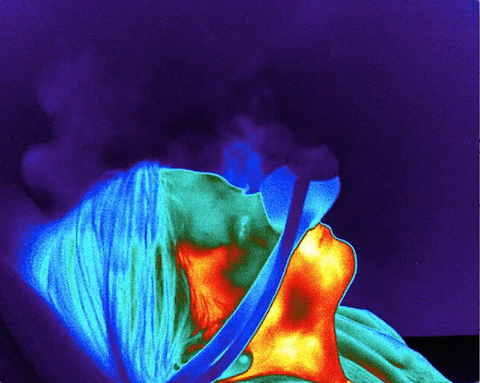

Spectral Filtering

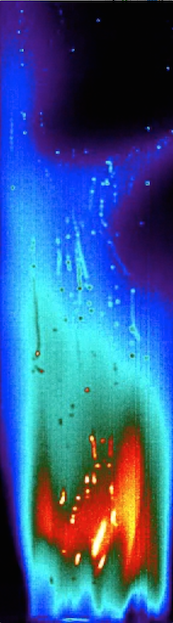

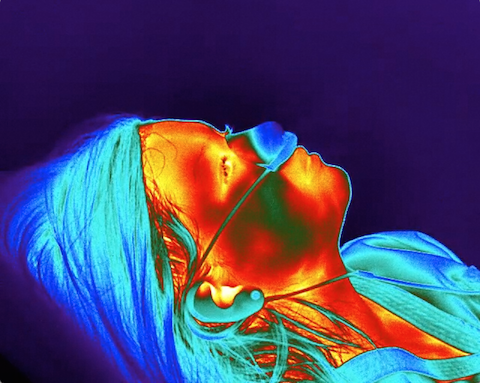

One of the great advantages of cooled thermal cameras is the ability to easily perform spectral filtering in order to uncover details and take measurements that otherwise would be unachievable with uncooled thermal cameras. In the first example shown here, we are using a spectral filter, either placed in a filter holder behind the lens or built into the dewar detector assembly, in order to image through flame. The end user wanted to measure and characterize the combustion of coal particles within a flame. Using a “see through flame” spectral infared filter, we filtered the cooled camera to a spectral waveband where the flame was transmissive and therefore were able to image the coal particle combustion. The first video is without the flame filter and all we see is the flame itself. The second is with the flame filter and we can clearly see the combustion of coal particles.

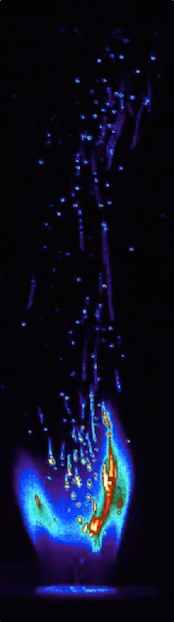

The second example uses a Nitrous Oxide filter that filters to where Nitrous Oxide is absorptive to the IR and therefore we can “see it” with the cooled thermal camera. The application was to design a better Nitrous Oxide mask and scavaging system; so the first video is imaging the older mask design and the second video is imaging the new mask design. As you can see, the older mask design is leaking a lot of Nitrous gas into the room, which is concerning for many reasons. The new mask design has minimal leakage and appears to be a better solution.

If you have an application challenge you'd like to share with Teledyne FLIR, fill out the contact form.