Tracing gas leaks: maintenance and safety problems highlighted

With more than 160,000 kilometres of piping of every imaginable kind, Shell Nederland Raffinaderij in Pernis (Rotterdam) is the largest oil refinery in Europe. Safety and environmental considerations are firmly embedded throughout the company, its quality systems and its production management processes. Shell has also adopted a stringent safety policy in which preventive maintenance is uppermost.

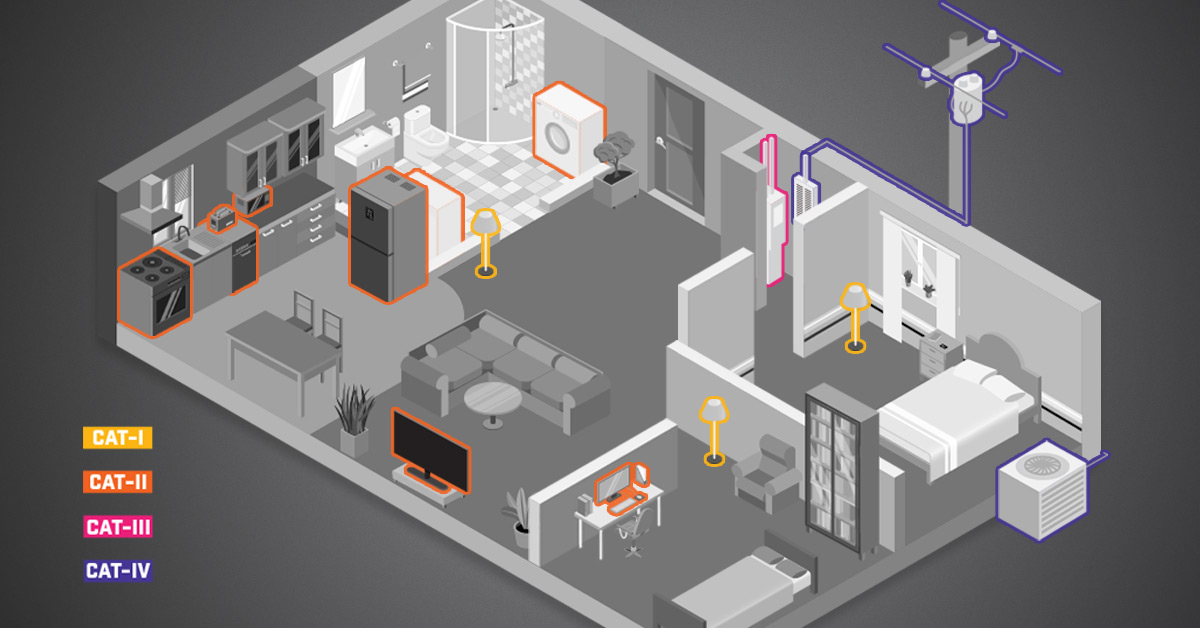

Many chemical compounds and gases are invisible to the naked eye. Yet many companies work intensively with these substances before, during and after their production processes. Strict regulations govern how companies are to trace, document, rectify and report any leaks of volatile gaseous compounds, and how often these procedures are to be carried out. The most commonly used technology is the ‘ToxicVaporAnalyzer (TVA) or ‘sniffer technology’. “When searching for potential gas leaks, we check all systems at points that may or may not have been identified beforehand. These checks are carried out regularly, and are particularly important following a shutdown.

At a refinery like the one we have here, this means carrying out tens of thousands tests on piping, stopcocks, seals, valves, torches, etc. Before we had the FLIR GasFindIR, an inspector using the TVA could carry out around five hundred inspections per day. An inspector using this infrared camera system can, on the other hand, get through an inspection regime of more than one hundred objects an hour. The most important reason for using the system is to minimise discharges of gas and other volatile organic substances from our pipework, particularly (potential) leaks around flanges and other gaskets”, explains Rutger Zoutewelle, research analyst at Shell Pernis.

Safe scanning

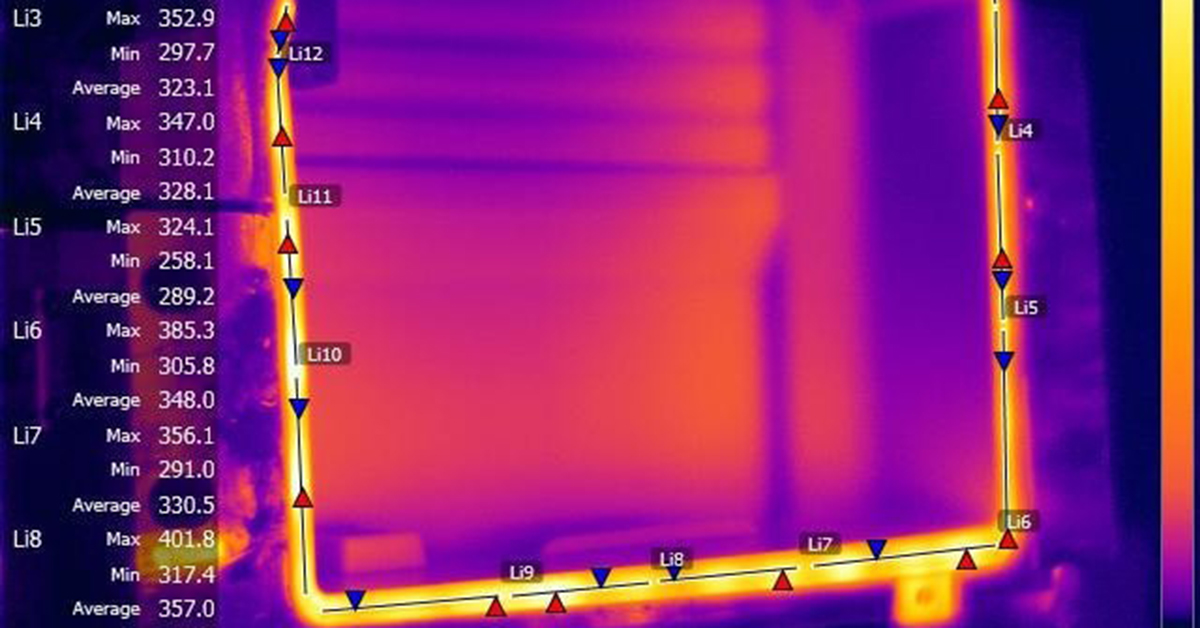

The key success factors for businesses today are safety, efficiency and profitability. When carrying out maintenance, it is of vital importance that maintenance engineers are able to obtain as complete a picture as possible of the condition of the plant. A thermal imaging system is an extremely important tool for tracing potential faults. Experience shows that up to 84 percent of leaks occur in less than 1 percent of the plant. This means that 99 percent of what are expensive, time-consuming inspection tools are being used to scan safe, leak-free components. Using the FLIR GasFindIR in this sector allows us to achieve enormous savings in terms of time and personnel.

The technologies currently in use may expose inspectors to invisible and potentially harmful chemicals, and do not allow for wind and weather factors that can produce inaccurate measurements. In addition, they can only tell us something about the test points that have been identified beforehand and only give readings within the immediate vicinity of the inspector. The infrared technology used by the FLIR GasFindIR shows gas emissions as a plume of smoke. When a leak has been identified from a safe distance using the device, the Toxic Vapor Analyzer can be used to determine the concentration percentage of the substance. Rutger Zoutewelle: “We heard about FLIR GasFindIR through our colleagues in Houston. Compared to how we did things before, using the camera for testing offers many advantages over more conventional technologies. The camera is a quick, non-contact measuring instrument that can also be used in hard-to-access locations. It also offers benefits in terms of safety and the environment”.

Benefits

The core of the GasFindIR is a cooled Indium Antimonide (InSb) detector. This detector produces clear images with a high level of detail. The camera, which weighs only 2.5 kg, has been designed for use in harsh industrial environments and operates within a wide temperature range of -15° C to +50° C. It produces infrared images in real-time in the widely used PAL format. It has an industrial shock rating of 40G. The camera can detect twenty different types of gas in real-time; these appear on the screen as ‘black smoke’. These characteristics mean that miles of piping can be scanned from a safe distance. Rutger Zoutewelle: “Most pipes, flanges, valves and other connections in petrochemical operations are free of faults. However, certain factors that are beyond our control could result in a small number of components not being hundred percent.

The positive experiences of our colleagues at the plant in Houston in using the system to trace leaks resulted in Shell Pernis deciding to introduce the technology here as well.” Anyone using the system has to go on a short training course and then needs a few days of on-the-job familiarisation to become fully conversant with the system. But, once you have got the hang of it, the camera offers many benefits. The camera is in constant use at the refinery and is always used following a shutdown. It’s an invaluable tool and a great preventive solution”.

A smart solution

Using thermal imaging techniques ‘in the field’ can place high demands on the equipment and the user: often a safe distance has to be maintained from the object being tested or, in other cases, the problem might be how to get close enough. Then you have to remember that the work may involve climbing, or hours at a time spent inspecting a major plant. Therefore, the size and weight of the equipment that inspectors have to carry around with them are important factors. “The GasFindIR contributes to the safety and the effective operation of our plants. It provides direct, tangible results and gives peace of mind”, concludes Rutger Zoutewelle. “It’s particularly useful when inspecting high pressure systems, as these are at the greatest risk of developing leaks. Here, the camera has become virtually indispensable”.

The camera can be used in a number of different ways to inspect plant safely. There are several major benefits to using thermal imaging techniques. These include the fact that systems do not have to be shut down during the inspection, measurements can be carried out remotely, rapidly and at relatively low cost and most important of all – problems can be identified at an early stage.

Using the GasFindIR, an inspector can get through an inspection regime of more than one hundred objects an hour. The most important reason for using the system is to minimise discharges of gas and other volatile organic substances from our pipework.