Measuring the heat generation of the fiber laser and utilizing it for optimization to produce higher power

Application story from the Center for Attosecond Laser Science, Graduate School of Science, The University of Tokyo

The cost effectiveness of introducing thermal imaging cameras is high when considering the risks of equipment damage.

![]()

This story is credited to Reza Amani, Project Associate Professor from the Center for Attosecond Laser Science, Graduate School of Science at The University of Tokyo.

Dr. Reza Amani utilizes thermal imaging cameras to measure heat that is generated on the gain fiber of a fiber laser, thereby preventing equipment damage or injuries to operators due to a rupture that may occur when temperature limits are exceeded. These cameras can help with giving instructions to students during experiments, improving safety for operators at on-site applications, and improving performance of the equipment, etc.

Reza Amani

Project Associate Professor

Center for Attosecond Laser Science, Graduate School of Science, The University of Tokyo

![]()

Monitoring temperature increases in order to prevent damage to fibers

Dr. Reza Amani is involved in research that not only contributes to the fields of physical chemistry through the development of high-power lasers but also that aims for greater cooperation with industry. Laser processing is introduced in the semiconductor industry as well as many other industries. It allows a wide range of materials to be processed and enables high-precision, ultra-fine processing. In particular, the fiber lasers that Dr. Amani is working on have high energy conversion efficiency and excel in terms of stability and reliability. In addition, since light is confined in the fibers, it does not require a clean room, and it is attracting attention because of its advantages such as electrical control and ease of handling.

“The core of optical fiber, which is referred as ‘gain fiber,’ is doped (added) with Er (erbium) and Yb (ytterbium). A laser output of 22 W or more can be acquired in a single mode, but the fiber is promptly heated after excitation. When the fiber reaches a certain temperature, it will first swell and then burst. Should this occur, equipment becomes useless, and there are risks of injuries.”

To prevent such risks, it is necessary to measure the heat that is generated on the gain fiber of the fiber laser and the experiment must be stopped before the temperature limit is reached and the external plastic of the cladding (acrylate coating) is destroyed. However, when gain fiber is created, it is unknown when it exceeds the temperature limit. As a mean to monitor the rise of temperature, Teledyne FLIR thermal imaging camera was introduced.

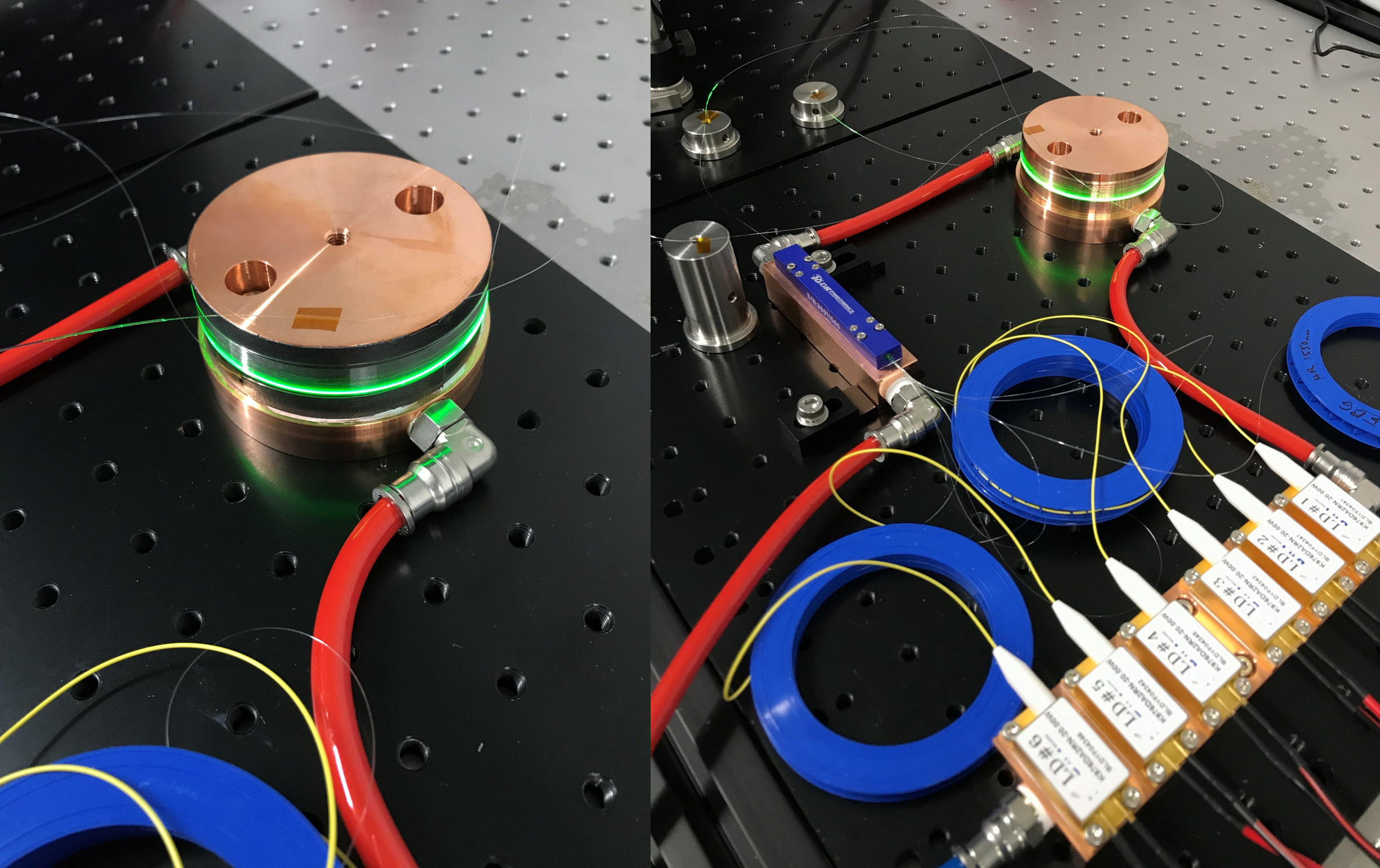

Gain fiber doped with Er and Yb ions. This gain fiber is coupled with a multi-mode 976-nm excitation laser to make a resonator. It can then oscillate with the central wavelength of 1,560 nm to output a single-mode laser of 22 W or more. Such a laser device can be applied to laser processing, excitation of a mid-infrared laser, and the field of optical communication, etc.

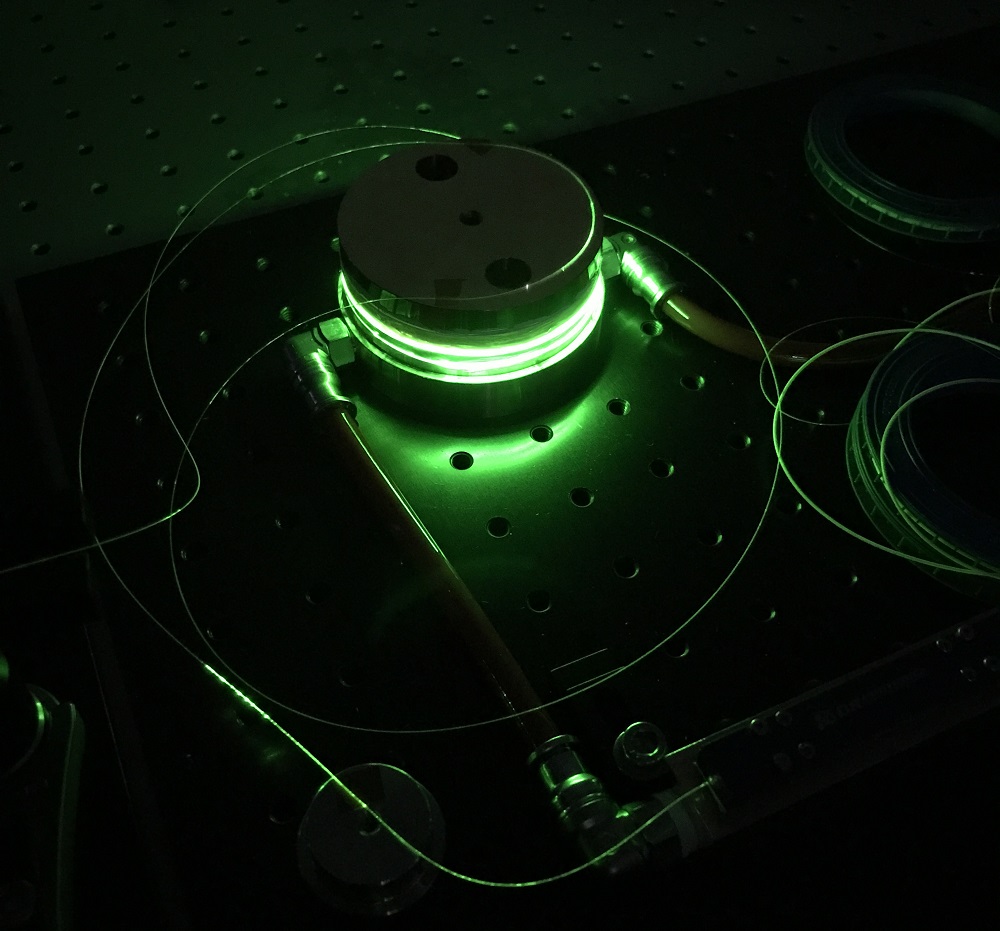

When the gain fiber doped with Er-Yb ions, a green fluorescent light is generated. The stronger the fluorescent light, the higher the absorption of the excitation laser and the amount of heat generation will become higher.

Select the Teledyne FLIR with high resolution and for easy analysis

Dr. Amani says that they tried to take measurements with a thermal imaging camera they had at the laboratory, but it had a low pixel-count, and due to the limited image resolution, the measured values were lower than the actual ones, effectively making it useless.

“In my previous job, I studied thin disk lasers and used a high pixel-count thermal imaging camera from FLIR. Therefore, I know a lot about the advantages of FLIR cameras. The fiber is as thin as 250 μm including the external plastic part, which is called the acrylate coating. Without a certain extent of resolution, we cannot precisely measure temperatures. However, I assumed my current position a year ago and have just started up my laboratory. Because of the limited budget, I chose the FLIR E54. It has a fair resolution and can be purchased at an academic price.”

Another reason for choosing Teledyne FLIR was that data taken can be analyzed on a PC. “We import the image data taken onto a PC and conduct a wide variety of analyses. It is difficult to precisely judge where heat generation occurs by just looking at the data on the spot, but by importing data to a PC, we can analyze in more detail. This is of course an advantage.”

![]()

Portable thermal imaging camera

FLIR E54

The FLIR E54 is FLIR's first handheld thermography camera, it can see the temperature distribution of objects with temperature differences in 320 × 240 pixel infrared resolution. Image correction with MSX® produces the sharpest images in its class. Interchangeable telephoto and wide-angle lenses are useful for investigations in various scenes. In addition, by connecting to PC software, it is possible to analyze and record time-series temperature changes as video.

Identify heat limits and procedures for optimization

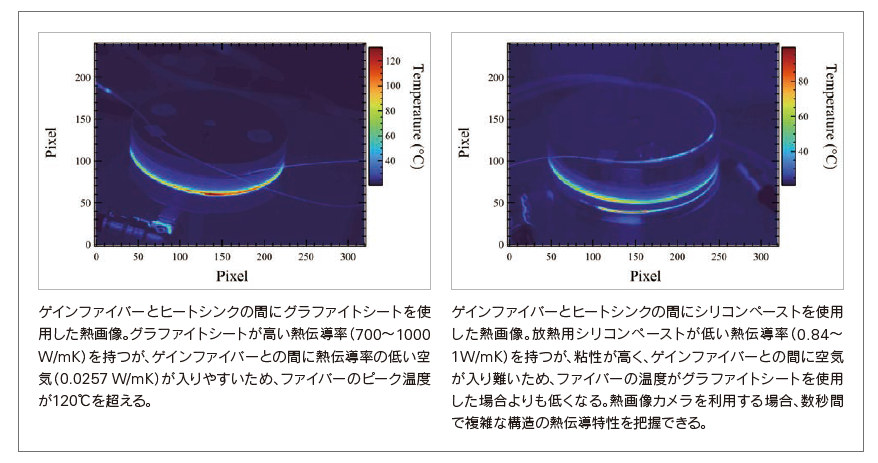

“We also use a thermocouple and other contact-type thermometers, but thanks to the thermal imaging camera, we are now able to find which parts tend to have high temperatures, based on temperature distributions.”

The upper withstanding temperature of the gain fiber is specified as 80°C. As the camera can precisely measure temperature distributions, the fiber can be used up to 110°C by properly removing the heat with a cooler. It is now possible to identify heat limits and procedures for optimization, thereby eliminating risks such as equipment damage and operator injuries.

“In Japan, I feel that research budgets are limited compared to other advanced countries. In other countries, thermal imaging cameras are a common tool that are used everywhere. I think they should be used more for R&D in Japan. If the fiber used in this research is destroyed by exceeding a heat limit, we will need to repurchase the equipment that costs about 300,000 yen. In consideration of this, the cost effectiveness of introducing thermal imaging cameras is not that bad.”

The industry has diverse requirements including processing different materials with a single laser. Processing multiple materials requires an increase in the output power which can lead to the issue of heat generation. Infrared cameras such as the FLIR Exx-Series are useful in these situations for thermal measurement, and can provide useful data for future laser research.